hardness test value for carbon steel|high carbon steel hardness chart : trading High-carbon steel has approximately 0.60 to 1.00% carbon content. Hardness is higher than the other grades but ductility decreases. . specifies a range of light loads using a diamond indenter to make an indentation which is measured . Resultado da Please sign in with your corporate credentials. For help signing in, click here, click here

{plog:ftitle_list}

2 dias atrás · Sobre Chubut pesa el pago de una deuda con el Fondo que, según quedó previsto en la gestión del exgobernador Mariano Arcioni, debía hacerse en 10 cuotas y ajustado por inflación a partir de 2024.

The Rockwell test is simpler to run and requires less sample . The Brinell hardness test is commonly used to determine the hardness of materials .High-carbon steel has approximately 0.60 to 1.00% carbon content. Hardness is higher than the other grades but ductility decreases. . specifies a range of light loads using a diamond indenter to make an indentation which is measured .

Reference Table: Steel hardness conversion chart - all values approximate. Brinell Hardness HB Rockwell HRC Rockwell HRB Vickers HV N/mm²; 800: 72---780: 71

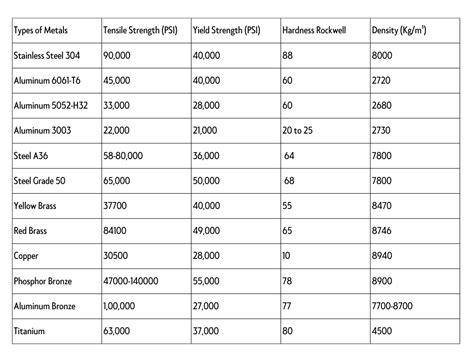

tensile strength chart for steel

The Rockwell hardness test is appropriate for hardness values ranging from 20-70HRC. If the hardness of the sample is less than 20HRC, it is recommended to use the HRB scale as the sensitivity of the indenter .It’s most commonly used to check the hardness of steel that’s been heat treated. Here’s the process: How to Use a Rockwell Testing Machine. . You can’t use the Rockwell method for testing the hardness of .020″ shim stock if it’s supposed to be 60 HRC. Just be aware that there are minimum thicknesses in the 0.040″ and under range .Hardness of Steels. High-carbon steel has approximately 0.60 to 1.00% carbon content. Hardness is higher than the other grades but ductility decreases. Brinell hardness of high-carbon steel is approximately 200 MPa. . Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing.Hardness Testing Hardness testing can best be described as a measurement of “resistance to penetration” to a defined load. Several types or methods of hardness testing are more common and found in this table. . Carbon Steel Flat Bar; Stainless Steel Flat Bar 17-4 PH Annealed Hot Rolled and Pickled; Carbon Steel Flat Bar 1018 Cold Finished;

The Brinell hardness testing process is the last process where the result is observed from hardness value and it can be concluded that by decreasing the hardness value of the welded structure, the brittle fracture risk and improve the ductility will be minimized. Keywords: post weld heat treatment, brinell hardness, carbon steel and SMAW.Carbon Steel: Carbon Steel | EN8 | 1.0503 | Fe. As machined. . Calibration and standardisation are critical to obtaining reliable and accurate hardness values using the Leeb hardness test method. Stay Connected! Proto Labs Ltd., Halesfield 8, Telford, Shropshire, TF7 4QN. Phone: +44 (0) 1952 683047 Email: [email protected]Low-carbon steel contains approximately 0.05–0.25% carbon making it malleable and ductile. . therefore its value does not depend on the size of the test specimen. However, it is dependent on other factors, such as the preparation of the specimen, .

Download scientific diagram | Vickers hardness test result for low, medium and high carbon steel samples from publication: In Vitro Microstructure, Mechanical Properties and Corrosion Behaviour of .The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. . Steel Hardness versus Strength; Brinell Vickers Rockwell Equivalent Rm; Impression Diameter (mm) Hardness HB. Hardness HV. Hardness B. Hardness C (ton f /in 2) (kg f /mm 2) (N/mm 2) 2.50: 601:

Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and yThe Vickers hardness number for carbon steel is 55-120HV5. If the test is conducted under a load value of 5 kgf, the Vickers hardness number would be in the range of 55 to 120 kgf/mm². As an estimate, the value may vary depending on the composition of carbon steel.

The Jominy test involves heating a cylindrical steel test piece to an austenitizing temperature (~980°–1010°C) and quenching (cooling) from one end, with a controlled and standardized jet of water. . Hardness testing of welds can be .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .Hence, for this test, 10 kgf was applied for 15 s to indent on the A333 Grade 6 low carbon steel specimen. The test was repeated on 5 different regions of the specimen, which include 4 edges and a midpoint of the sample. . Meanwhile, .

K) Temperature, °C (°F) 461: 20-100 (68-212) . Temper to desired hardness: SAE steel: Normalizing temperature, °C (°F .About High-Carbon Steel Tool steel refers to a variety of carbon and alloy steels that are particularly well-suited to be made into tools. High-carbon steel has approximately 0.60 to 1.00% carbon content.Hardness is higher than the other grades but ductility decreases. They are almost always used in a hardened and tempered condition and, as such, are especially wear .

It is generally not classified as non-destructive testing. 6. The hardness value of Rockwell hardness is a dimensionless number, with no unit. (Therefore, it is incorrect to refer to the Rockwell hardness as a degree.) . The C-curve in heat treatment reveals the fascinating transformation of carbon steel's microstructure during cooling. This . The steel with a carbon content of 0.18 showed an improvement in hardness, while the steel with a carbon content of 0.32 showed a decrease in hardness values [6]. In the study of Ourrad et al. [7], the space of an electric oven was heated to a temperature of 950 degrees, and after that, the water, oil, and mechanical properties were hardened .

The Brinell hardness values, which were measured using a 10 mm ball (HBW 10/3000) for individual sets, did not differ by more than 5% from the Brinell hardness values measured using the 5 mm ball (HBW 5/750). However, in the case of the historic steels (sets 1÷4), the HBW 10/3000 value is higher than the HBW 5/750 value.

In Brinell hardness test, a steel . indentation cannot be m ade on the specimen and correct value of the hardness . This was carried out by heating samples of low carbon steel to a specific . The tensile strength of materials can be estimated from hardness test results, which is a widely used method in engineering practice. At present, the main domestic standards that can be used for this purpose are GB/T 33362-2016 Conversion of Hardness Values of Metallic Materials and GB/T 1172-1999 Conversion of Hardness and Strength of Ferrous .Using the Rockwell Hardness measurement equipment with diamond braille indenter (Scale C), take measurements from the end at 1/8th inch increments up to 1/2 inch, then 1/4 inch increments up to 2 inches. Round each hardness value to the nearest integer, and discard any values near the end that seem especially low since oxidation has occurred andRockwell Hardness Testing Reference Guide Newage Hardness Testers Selection Guide Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. .

ASTM A36 Steel. ASTM A36 steel is one of the most widely used carbon structural steels, although the carbon content of A36 material is maximum 0.29%, it is considered to be the mild steel (content of carbon ≤ 0.25%).. A36 mild steel is often compared to AISI 1018, A36 carbon steel is commonly hot rolled, while 1018 steel is commonly cold rolled.. Notes: There are two .

high carbon steel hardness chart

Bursting Tester solution

carbon steel tensile strength chart

webWant to play YoHoHo.io? Play this game online for free on Poki in fullscreen. Lots of fun to play when bored. YoHoHo.io is one of our favorite .io games.

hardness test value for carbon steel|high carbon steel hardness chart